When using CCR glass clear epoxy , it is an advantage to follow these six tips. They apply to all similar casting epoxies, such as X-cast , glasscast and ecopoxy. Before you start, make sure you have protective equipment such as gloves and safety glasses, and that you work in a well-ventilated room or use a respirator according to the safety data sheet for the product you are using.

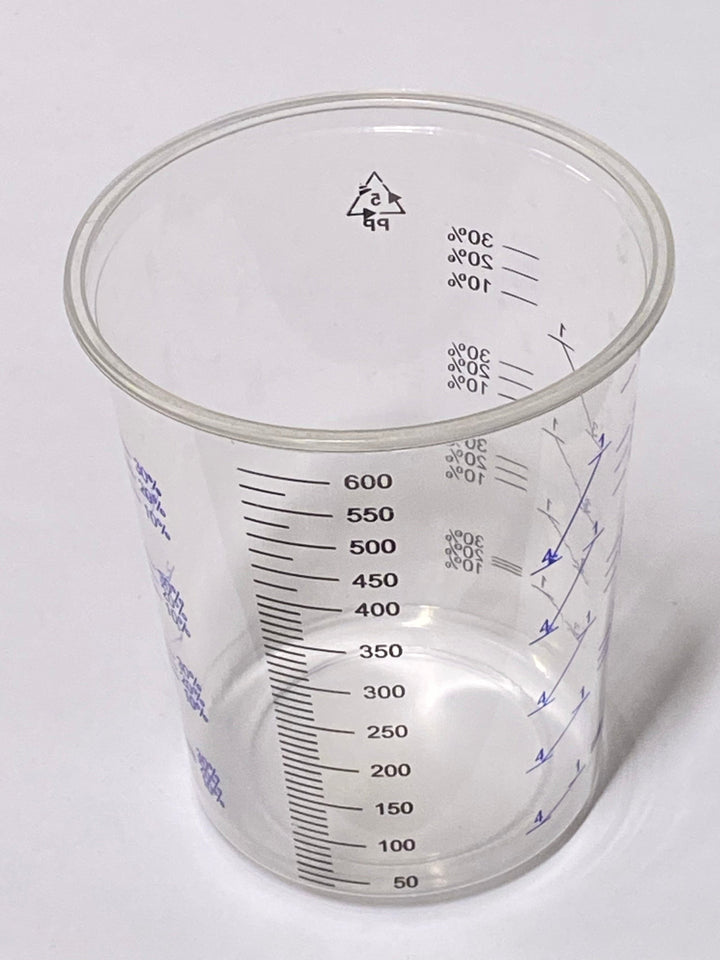

1. Use of suitable mixing cups

Use a clean mixing cup made of plastic, cardboard or silicone that has smooth edges that you can scrape when mixing the epoxy. It is important to have a smooth surface that you can reach with your mixing sticks to ensure that everything is mixed.

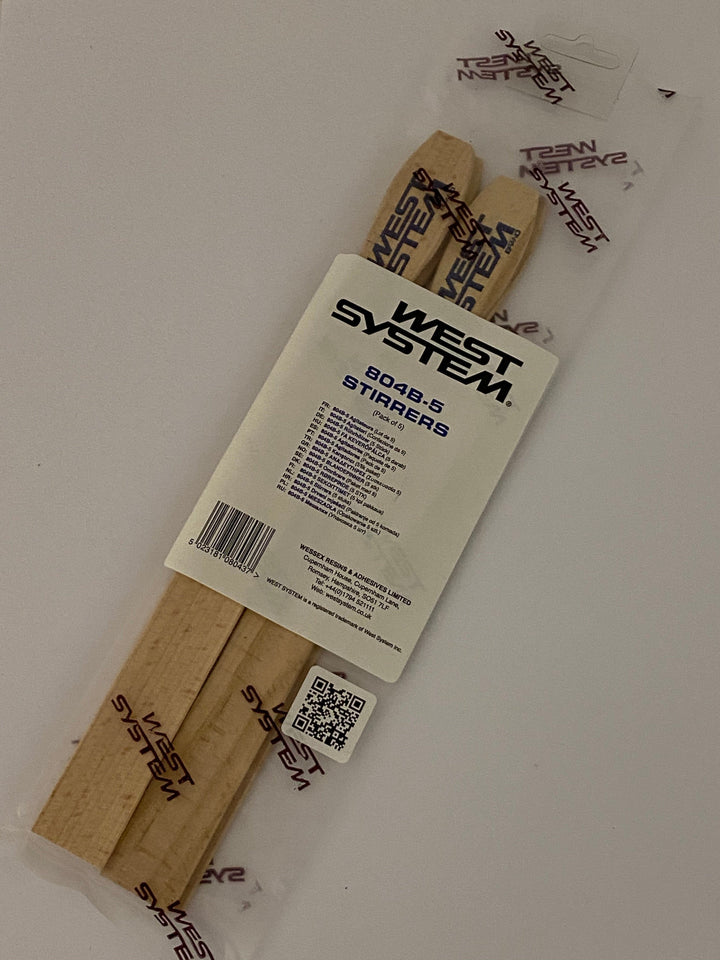

2. Use of suitable mixing sticks

Use stir sticks that are suitable for reaching all parts of your mixing cup to scrape the bottom and sides so you can mix the epoxy properly. This often means a stir stick that has a flat bottom and 90 degree sides.

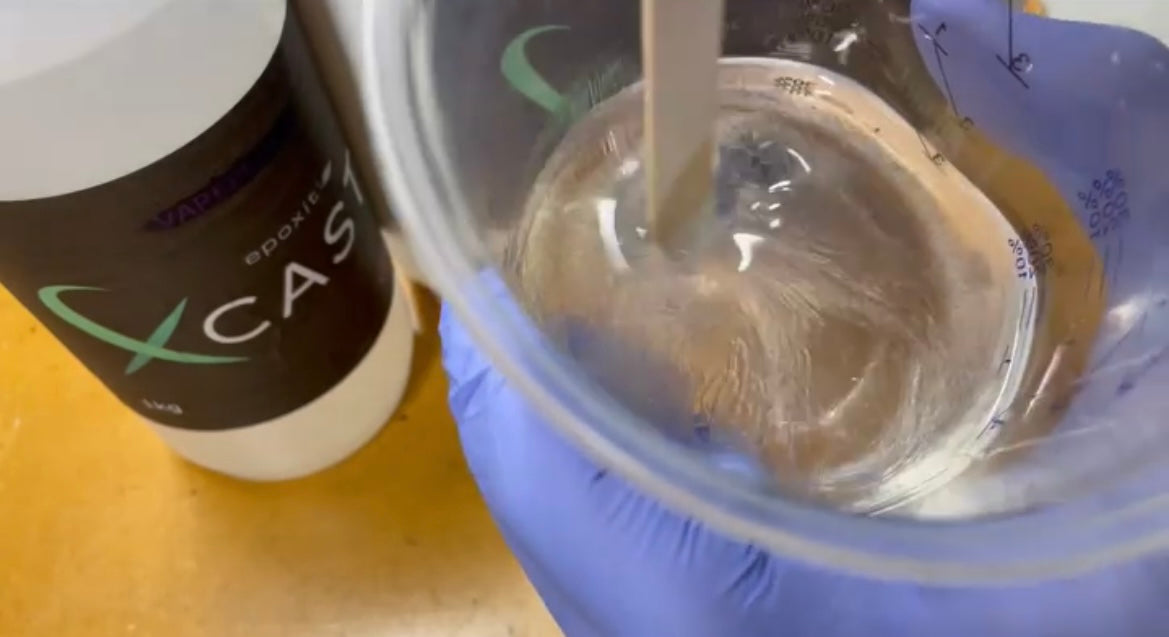

3. Scrape the sides and bottom of the mixing cup

Avoid uncured epoxy in your project by scraping the bottom and sides of the mixing cup thoroughly several times while mixing the epoxy. This ensures that all unmixed resin and hardener are included in the mixture and you get full integration so that all the material reacts and cures.

4. Check if the streaks are gone

When you mix the epoxy you will see streaks in the epoxy that show the separation between resin and hardener, as you mix the streaks will disappear and the epoxy will become clear. This is how you can tell when the epoxy is fully mixed. Again, make sure to scrape the sides and bottom well.//

5. Stir slowly to avoid bubbles and spills

To get a clear finish it is important to stir slowly. Mixing quickly can cause spills and small bubbles which can affect the clarity of the final epoxy, so mix slowly to reduce bubbles and spills.

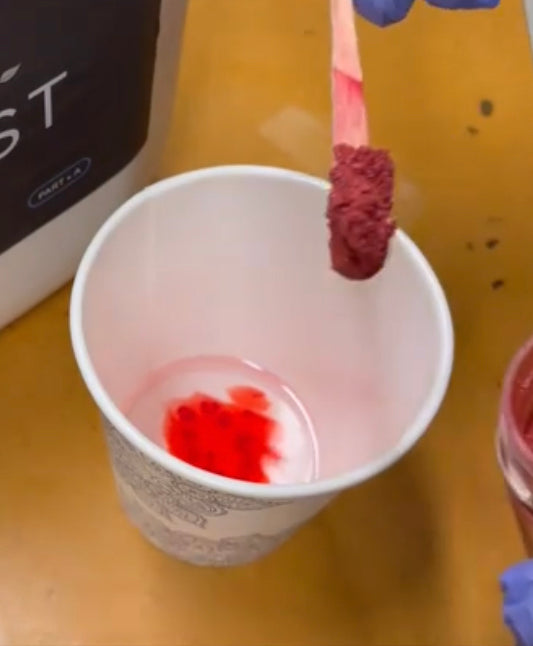

6. Mix properly

Complete mixing is essential for a good result with fully cured epoxy. Mix well before adding color. For small mixtures, for example a few deciliters, you must mix for at least 1 minute, but it is recommended to mix also after all streaks are gone and scrape the bottom and sides extra well. To be absolutely sure to avoid getting unmixed resin on top of the cast, you can transfer the mixed epoxy to a new mixing cup, and continue mixing there for one more minute before emptying the epoxy into the project.

Bonus tip: Check if you are an epoxy expert

After the epoxy has cured, pop the epoxy out of the mixing cup and check with your finger the underside of the epoxy, that is, what has been against the walls and bottom of the mixing cup. If it is sticky, you have not mixed the epoxy well enough. If it is completely smooth and hard, you are an epoxy expert. Congratulations!

3 comments

Line

Passer denne til smykkelaging

Martin fra Storbua

Hei Aigin! Ja, vi arrangerer ikke kurs per nå, men vi kan gjerne lære deg noen tips og triks. For å komme igang, fortell meg gjerne litt mer om hva du ønsker å lage, så kan jeg gi deg en skreddersydd fremgangsmåte og tipsliste. Vi kan gjerne sparre med deg på hvordan du skal gå frem for å få ønsket resultat. Bare send oss en epost eller en chatmelding.

Aigin Angakkoq Gaup

Hei der!

Spennende med epoxy.. Men æ lurer på om dere avholder kurs i dette feltet?, samt hvor mye det koster.. Æ har lyst å lære meg mere av dette.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.